| Contact Us |

| ADD: |

| Shangnian Industrial Area, Huang Yan, Tai Zhou City, Zhe Jiang Province, 318020, China |

| TEL: |

| 0086-576-88807095/84015050 |

| FAX: |

| 0086-576-88807035/84015086 |

| E-mail: |

| machinery@watongroup.com |

|

|

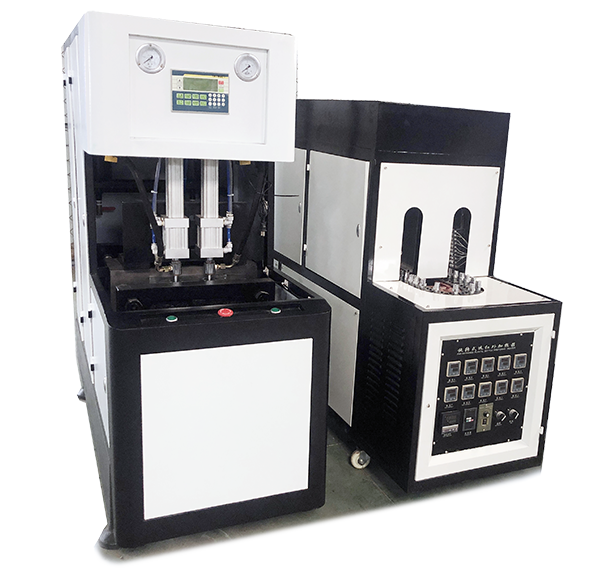

| MS Semi-automatic Machine |

|

|

MS Series Semi-automatic Blow Molding Machine

Features:

- Wide application, can make any PET bottles with any shape from 50ml to 20L.

- PLC control, easy operation.

- Using the new clamping system with double crank four tie-bars, the cross balanced fixed glide, strong clamping force.

- With Pre-blow function, produce higher quality PET bottles, lower defective rate.

- Advanced air circuit design, low pressure for clamping, sealing and stretching; high pressure for blowing bottles.

- With infrared heating, every layer can be adjustable independently, frequency speed control, cooling air for neck cooling, achieves perfect bottle.

ITMES |

|

Machine Models |

Unit |

MS-2L |

MS-2L/4 |

MS-5L-1 |

MS-5L-2 |

MS-10L-1 |

MS-20L |

Cavity Qty. |

cav. |

2 |

4 |

1 |

2 |

1 |

1 |

Max.Bottle Volume |

กก |

3L |

3L |

5L |

5L |

10L |

20L |

Neck size |

mm |

18~48 |

18~38 |

18 ~ 80 |

18 ~ 80 |

38 ~ 120 |

38 ~ 120 |

Max. Bottle Dia. |

mm |

105 |

105 |

190 |

190 |

200 |

300 |

Max.Bottle Height |

mm |

360 |

350 |

350 |

350 |

420 |

550 |

Theoretical Output |

BPH |

700-1,000 |

1,400-2,000 |

300-400 |

500-700 |

300-500 |

60-120 |

MaxHeating Power |

KW |

19 |

28 |

28 |

45 |

50 |

50 |

Install Power |

KW |

22 |

29 |

29 |

46 |

52 |

52 |

Blowing Pressure |

Mpa |

2.5 ~ 4.0 |

2.5 ~ 4.0 |

2.5 ~ 4.0 |

2.5 ~ 4.0 |

2.5 ~ 4.0 |

2.5 ~ 4.0 |

Motion Pressure |

Mpa |

0.8 ~ 1.2 |

0.8 ~ 1.2 |

0.8 ~ 1.2 |

0.8 ~ 1.2 |

0.8 ~ 1.2 |

0.8 ~ 1.2 |

Blower Size |

M |

1.65 X 0.65 X 1.70 |

1.6 X 0.82 X 2.1 |

1.95 X 0.65 X 1.80 |

1.9 X 0.9X 1.80 |

1.9 X 0.7 X 1.70 |

2.5 X 0.8 X 1.9 |

Oven Size |

M |

1.7 X 0.58 X 1.35 |

1.52 X 0.58 X 1.31 |

1.8 X 0.6 X 1.37 |

2.1X 0.6 X 1.35 |

2.1X 0.6 X 1.35 |

2.6X 0.7 X 1.58 |

Machine Weight |

KGS |

900 |

1,200 |

820 |

1,000 |

1,100 |

1,450 |

|

Due to continous technical development, specification would be updated without prior notify. |

|

|