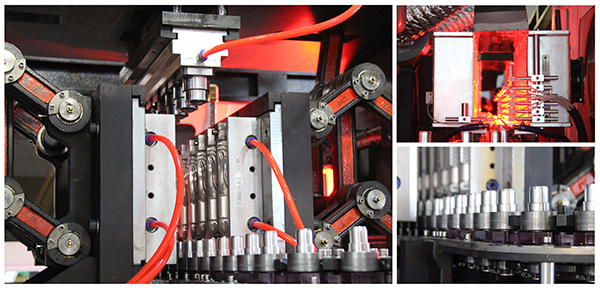

TURBO Series High-speed Blow Molding Machine

(Full Servo Auto models for bottles <2L)

Features:

- Full Servo control 4 main structures: Feeding, Shifting, Clamping, Stretching.

Preform Feeding System: high speed and precisely positioning;

Preform Transfer System: double the speed of preform moving, overall simplified motion;

Mold Clamping System: reaction time is reduced to 50%, simple structure, long use life;

Stretch System: Servo Motor precisely control, flexible adjustment improves bottle quality.

- Advanced PTO System (Pulse/Train/Output Servo Positioning Module) works on high speed positioning, with higher speed, higher noise immunity and precise positioning.

- High speed, stable, low noise, 500ml production 6-cavity model capacity 10,000BPH, 9-cavity model 13,000BPH.

ITEMS |

Unit |

TURBO-4L |

TURBO-6S |

TURBO-6L |

TURBO-9S |

Theoretical Output |

BPH |

4,500 - 5,500 |

9,000 ĘC 10,000 |

6,500 - 8,000 |

12,000 ĘC 13,000 |

Molding |

Cavity Pitch |

mm |

114.3 |

76.2 |

114.3 |

|

Cavity Qty. |

cav. |

4 |

6 |

6 |

9 |

Bottles |

Max. Bottle Volume |

|

2L |

750ml |

2L |

750ml |

Neck size |

mm |

18 ~38 |

18 ~38 |

18 ~38 |

18 ~38 |

Max. Bottle Diameter |

mm |

105 |

70 |

105 |

70 |

Max. Bottle Height |

mm |

330 |

260 |

330 |

260 |

POWER |

Max Heating Power |

KW |

50 |

65 |

85 |

85 |

Install Power |

KW |

60 |

70 |

90 |

90 |

Air Supply |

Blowing Pressure |

Mpa |

2.5 ~ 4.0 |

2.5 ~ 4.0 |

2.5 ~ 4.0 |

2.5 ~ 4.0 |

Motion Pressure |

Mpa |

0.8 ~ 1.2 |

0.8 ~ 1.2 |

0.8 ~ 1.2 |

0.8 ~ 1.2 |

Machine size |

Main Machine Size |

M |

3.5 X 2.0 X 2.3 |

4.3X 2.15 X 2.25 |

5.8X 2.2 X 2.3 |

5.8X 2.2 X 2.3 |

Preform-Unscrambler Size |

M |

1.1 X 0.9 X 2.4 |

1.3 X 0.6 X 2.75 |

1.4 X 0.8 X 3.03 |

1.4 X 0.8 X 3.03 |

Auto-loader Size |

M |

0.97 X 2.5 X 3.2 |

1.16 X 1.6 X 3.3 |

1.16 X 1.6 X 3.3 |

1.16 X 1.6 X 3.3 |

Machine Weight |

KGS |

5,000 |

5,500 |

8,000 |

8,000 |

|